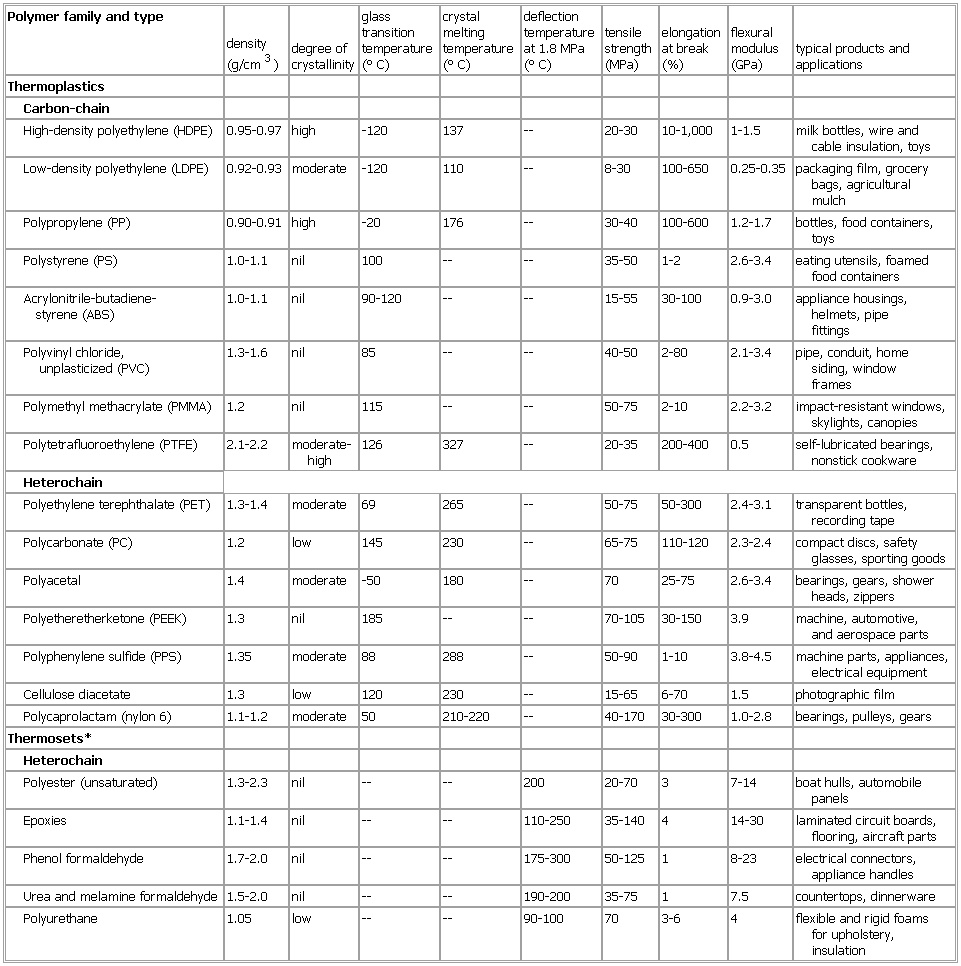

- Properties and Applications of Commercially Important Plastics, Table

-

▪ TableTable 1: Properties and Applications of Commercially Important PlasticsPolymer family and type density(g/cm3) degree ofcrystallinity glasstransitiontemperature(° C) crystalmeltingtemperature(° C) deflectiontemperatureat 1.8 MPa(° C) tensilestrength(MPa) elongationat break(%) flexuralmodulusapplicationsThermoplasticsCarbon-chainHigh-density polyethylene (HDPE) (industrial polymers, major) 0.95-0.97 high -120 137 — 20-30 10-1,000 1-1.5 milk bottles, wire andcable insulation, toysLow-density polyethylene (LDPE) (industrial polymers, major) 0.92-0.93 moderate -120 110 — 8-30 100-650 0.25-0.35 packaging film, grocerybags, agriculturalmulchPolypropylene (PP) (industrial polymers, major) 0.90-0.91 high -20 176 — 30-40 100-600 1.2-1.7 bottles, food containers,toysPolystyrene (PS) (industrial polymers, major) 1.0-1.1 nil 100 — — 35-50 1-2 2.6-3.4 eating utensils, foamedfood containersstyrene (ABS) (industrial polymers, major) 1.0-1.1 nil 90-120 — — 15-55 30-100 0.9-3.0 appliance housings,helmets, pipefittingsunplasticized (PVC) (industrial polymers, major) 1.3-1.6 nil 85 — — 40-50 2-80 2.1-3.4 pipe, conduit, homesiding, windowframesPolymethyl methacrylate (PMMA) (industrial polymers, major) 1.2 nil 115 — — 50-75 2-10 2.2-3.2 impact-resistant windows,skylights, canopieshigh 126 327 — 20-35 200-400 0.5 self-lubricated bearings,nonstick cookwareHeterochainPolyethylene terephthalate (PET) (industrial polymers, major) 1.3-1.4 moderate 69 265 — 50-75 50-300 2.4-3.1 transparent bottles,recording tapePolycarbonate (PC) (industrial polymers, major) 1.2 low 145 230 — 65-75 110-120 2.3-2.4 compact discs, safetyglasses, sporting goodsPolyacetal (industrial polymers, major) 1.4 moderate -50 180 — 70 25-75 2.6-3.4 bearings, gears, showerheads, zippersPolyetheretherketone (PEEK) (industrial polymers, major) 1.3 nil 185 — — 70-105 30-150 3.9 machine, automotive,and aerospace partsPolyphenylene sulfide (PPS) (industrial polymers, major) 1.35 moderate 88 288 — 50-90 1-10 3.8-4.5 machine parts, appliances,electrical equipmentPolycaprolactam (nylon 6) (industrial polymers, major) 1.1-1.2 moderate 50 210-220 — 40-170 30-300 1.0-2.8 bearings, pulleys, gearsThermosets*HeterochainPolyester (unsaturated) (industrial polymers, major) 1.3-2.3 nil — — 200 20-70 <3 7-14 boat hulls, automobilepanelsEpoxies (industrial polymers, major) 1.1-1.4 nil — — 110-250 35-140 <4 14-30 laminated circuit boards,flooring, aircraft partsPhenol formaldehyde (industrial polymers, major) 1.7-2.0 nil — — 175-300 50-125 <1 8-23 electrical connectors,appliance handlesUrea and melamine formaldehyde (industrial polymers, major) 1.5-2.0 nil — — 190-200 35-75 <1 7.5 countertops, dinnerwarefor upholstery,insulationSee as table:

*All values shown are for glass-fibre-reinforced samples (except for polyurethane).

*All values shown are for glass-fibre-reinforced samples (except for polyurethane).* * *

Universalium. 2010.